Hello, my friend. Are you having problems in transporting cement? Transporting cement with a Pneumatic dry bulk trailer is a great way. So let’s talk about what is a pneumatic trailer, how does a pneumatic trailer work, design, spec, and more.

Part1. What is a pneumatic trailer?

Pneumatic trailers are also known as dry bulk trailers and pneumatic tank trailers. They have what looks like a lot of conical hoppers on the bottom. It is used to transport cement, fly ash, lime powder, ore powder, granular alkali, and other particles with a diameter of not more than 0.1mm powder dry materials.

3 Axle 50 Ton Fly Ash Bulker Truck

The Pneumatic trailer is composed of several hoppers, each of which is connected to a pipe at the bottom for unloading. The number of hoppers is determined by the capacity of the pneumatic dry bulk trailer, the larger the pneumatic tanker capacity, the greater the number of hoppers.

Related: What is a bulk cement trailer

Part2. How to operate a pneumatic trailer?

Loading and unloading the pneumatic trailer is a very simple task. Using a pneumatic trailer to transport cement can greatly improve transportation efficiency and speed up the project schedule.

2.1 How to load a pneumatic trailer?

- Begin by opening the pressure relief valve to release any remaining compressed air in the tank.

- Next, remove the filling manhole cover and position the filter appropriately.

- Proceed to load the cement into the tank steadily.

- After loading is complete, carefully clean any cement residue from the sealing ring, then securely close the manhole cover.

- Finally, close the pressure relief valve and inspect other valves, including the discharging butterfly valve, to ensure they are secure and prevent any cement leakage during transportation.

2.2 How to unload pneumatic trailer fast?

- Begin by connecting the pneumatic trailer discharge pipe. Ensure the seal ring is closed during this process. Initially, open the front and rear air chamber’s inlet and outlet valves. Then, proceed to close the following valves: pressure relief ball valve, external air source ball valve, secondary air ball valve, and discharge butterfly valve.

- Start the engine and air compressor smoothly. Allowing the air compressor to reach its rated speed and begin inflating the cement tank.

- As the pressure ascends to 0.15Mpa, open the secondary air ball valve. This action cleans the discharge pipe and confirms it is not obstructed. After this step, close the secondary air ball valve.

- When the pressure reaches 0.2Mpa, initiate the unloading process by opening the discharge butterfly valve.

- Next, close the front air chamber, allowing only the rear air chamber to intake. Monitor the pressure gauge: if the pressure increases, indicating that unloading has not occurred.

- If the pressure gauge does not indicate a rise, it signals that the rear chamber has completed unloading. Following this, open the front air chamber’s balloon valve, applying the same principle used for the rear air chamber.

- Finally, verify that no residue remains in the front and rear air chambers. Once confirmed, turn off the engine and the air compressor. Open the pressure relief ball valve, close the discharging butterfly valve, disconnect the unloading quick joint, remove the hose, and securely place it back in the vehicle. With these steps completed, the unloading job is successfully concluded.

Part3. Penumatic trailer unloading principle

The Pneumatic trailer is unloaded using the principle of fluidization, the tank has an internal fluidized bed with air holes. Through the air, the powder is fluidized and then unloaded.

3.1 What is Fluidization Principle?

When a powder is exposed to a gas at specific levels, it begins to exhibit properties akin to those of a liquid. This phenomenon is known as fluidization. In this process, the powder—a collection of solid, granular materials—transforms into a dynamic, fluid-like state, akin to a liquefaction process.

Gas is introduced from the bottom section of a chamber designed to transport solid particles to initiate fluidization. This gas causes the particles to move upward through the bed, filling the empty spaces between the particles.

At low gas velocities, the aerodynamic drag on the particles is minimal, allowing the bed of particles to remain in a stable, fixed state.

As gas velocity increases, however, a pivotal change occurs. The aerodynamic drag forces start to oppose the gravitational forces acting on the particles. This opposition causes the bed to expand volumetrically, as the particles begin to separate from one another.

When the gas velocity reaches a critical point, the upward drag forces equal the downward gravitational forces. At this juncture, the particles achieve a suspended position within the fluid, appearing to float amidst the gas.

As the fluid velocity continues to rise beyond this point, the behavior of the particles evolves further, and true fluidization takes place. In this state, the particles flow and interact much like a fluid, showcasing the remarkable transformation that this process engenders.

Part4. How many types do pneumatic trailers have?

The common pneumatic trailer is divided into four types, w type pneumatic dry bulk trailer, v-type cement trailer, tilt-type cement trailer & cement tanker truck.

The pneumatic trailer is differentiated according to the structure not used, and different pneumatic trailers can be used in different situations. So, when we buy, we should prioritize our use, the place of use, road conditions, local laws and regulations, and so on. At the same time, we should decide whether we should buy or rent based on the revenue.

4.1 W type penaumtc trailer

W type pneumatic trailer consists of several hoppers. For long distance transportation and large quantities of cement requiring water storage, the w-type pneumatic trailer is used.

4.2 V type cement trailer

A V-type cement trailer, also known as a V-shaped cement bulker or silo trailer, is a specialized type of semi-trailer designed to transport bulk powder materials, specifically cement. This cement trailer is engineered to be both efficient and safe, making it a preferred choice in the construction and transportation industries.

4.3 Tilt cement trailer

Tilt cement tanker, as the name suggests, is mainly used for unloading by gravity, by raising one side of the tank and then unloading it.

Related: How to unload and load dry bulk cement tanker trailer

Tilt cement tanker has very little residue because of their unique design, but their unloading speed is not so fast, and nowadays, tilt cement tanker is rarely seen.

4.4 Cement tanker truck

The Cement tanker truck does not need a separate tractor to power it, the tractor and semi-trailer are integrated, but it can only transport a small amount of cement at a time, if you need to transport a large amount of cement, you need to use cement trailers.

Bulk Cement Tanker Trailer Capacity Height

Part5. Specification of pneumatic trailer

The pneumatic trailer has 25-120 ton, 20-100cbm, different pneumatic trailer has different size, load capacity, configuration, etc. Below are some of the pneumatic trailer specifications.

| Brand | PANDA Mech |

| Volume | 20-100 cbm |

| Capacity | 25-120 ton |

| Engine | WeiCai Deutz diesel moto |

| Manhole Cover | 2 to 4 sets 500mm diameter |

| Dimension | 8500-13500*2500*3500-4000 mm |

| Tank Material | 5mm or 6mm high strength steel / stainless steel / aluminum |

| Structure | Q345 high straight steel |

| Landing Gear | JOST 28T |

| Suspension | Mechanical or air suspension |

| Brake System | T30/30 chamber, WABCO emergency valve |

| Axle | 2/3/4 axles, 13,16,20 ton axles, BPW or SAF |

| Tire | 12R22.5, 385/65R22.5, 13R22.5, 12.00R24, 315/80R22.5 |

| Parts | Pneumatic handrail, Famous brand engine, Axle, Tire, Water-proof wires, Semi-meter pipe, Valves, Release valve, Inner airbag, Landing gear, Water spray device, Side guard and toolbox, Manhole cover, blower |

Part6. Detail of pneumatic trailer

6.1 Diesel Engine and Compressor

The air compressor needs diesel engine to provide power, through the air compressor, the inside of the tank will be injected with air, so that the inside of the tank cement becomes a fluidized state.

The air compressor is very important for the unloading speed of the cement, it is the guarantee of the unloading efficiency and reliability of the powder material, so you must choose a reliable brand, such as Weichai and so on.

6.2 Design of pneumatic trailer

The design of pneumatic trailer is divided into four types, namely v type, w type, and tipper cement bulker.

Although they are different in appearance, but they all serve the same purpose, only in different countries and regions, the type of use is different.

6.3 load method of pneumatic trailer

While the common way of loading a pneumatic trailer is through the top manhole cover, we have invented a self-loading cement bulker, which can also be loaded by self-priming.

6.4 Capacity of pneumatic trailer

Panda Mech supply 25-120 ton cement trailers for sale. The minimum loading of pneumatic trailer is 25 tons, and the maximum loading can be 120 tons, in China, few pneumatic tanker trailer factories can produce 120 tons pneumatic trailer.

It is important to know that when the capacity of the pneumatic truck is more than 60 tons, the requirement of material and design will become higher, which is one of the advantages of Panda Mech pneumatic tanker.

6.5 Safety devices

In order to ensure the safe use of the pneumatic trailer, usually the pneumatic cement trailer is equipped with the following safety devices:

Pressure gauge: detects the internal pressure of the tank, usually when the air compressor is working.

Boost-blowing valve: It is used to assist the flow of powder and prevent the powder material from getting stuck in the pipe opening.

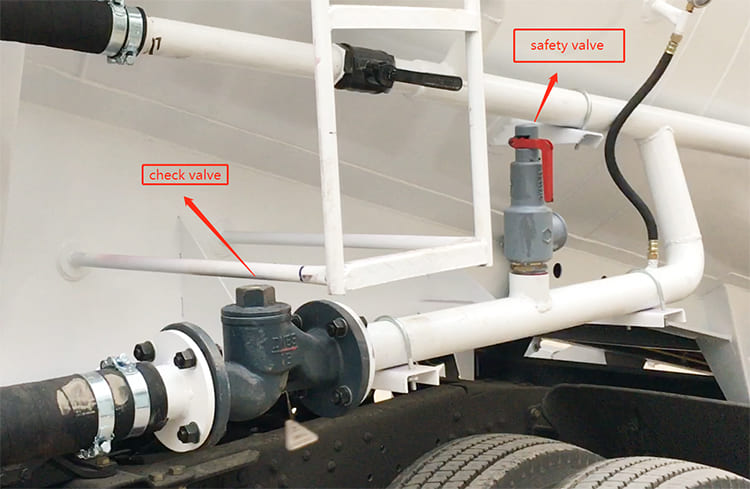

Safety Valve: Ensures that the pressure inside the tank is within a safe range, once exceeded, the safety valve will start to work.

Check Valve: The direction of airflow is not fixed, the use of check valves can prevent the compressed air backflow.

6.6 Walking system

The travel system includes tires, axles, lugs, leaf springs, and suspension. According to different road conditions, we will recommend the most cost-effective configuration for you.

Conclusion

Pneumatic trailers are used to transport cement, fly ash, lime powder, ore powder, granular alkali, and other particles with a diameter of not more than 0.1mm powder dry materials. Pneumatic bulk trailer has many different configurations, depending on the weight to be transported and the road conditions and local laws, we will recommend the most suitable pneumatic trailer for you. We will recommend the most suitable pneumatic trailer for you, depending on the weight and road conditions, as well as local laws. Any questions about pneumatic trailers, please feel free to contact Panda Mech.