Save Budget, Keep Safety - Bomb Cart Manufacturer

- Factory direct supply, transparent pricing.

- High durability + low maintenance frequency.

- After-sales service and spare parts support

- Handles 20–45ft containers, single or twin 20ft loads.

- Optimized deck and guides speed up container loading cycles.

Are containers piling up in your yard, costing you time and money? Then it’s time to upgrade to a Bomb Cart Trailer. Designed for intensive port operations, it helps you move loaded containers faster, cut tractor idle time, reduce traffic congestion, and lower your cost per TEU—while keeping operations safe and stable.

We provide bomb cart trailers tailored to different terminal layouts and equipment. You can choose 40ft or 45ft bomb carts, dual-20ft container bomb carts, heavy-duty multi-axle models for high-volume routes, skeletal bomb carts, and fully customized terminal container trailers engineered to match your existing tractors, RTGs, and yard cranes.

Table of Contents

Bomb Cart Trailer For Sale

Didn’t find what you are looking for? Tell us what you need.

Testimonials & Customers Review

More about Bomb Cart Trailer

Specification of bomb cart trailer

| Specification | 40Ft Bomb Cart Trailer | 45Ft Bomb Cart Trailer |

|---|---|---|

| Dimension (mm) | 12,613 × 2,810 × 1,508 | 14,138 × 2,810 × 1,820 |

| Loading capacity (ton) | ≤ 65T | 65T |

| Axles | 2 axles, 13T/16T, FUWA / BPW / TITAN brand | 2 axles, 13T/16T, FUWA / BPW / TITAN brand |

| Tire | 9 units, 12.00R22.5 or 315/80R22.5 | 9 units, 12.00R22.5 or 315/80R22.5 |

| Rim | 9.00-22.5 or 9.75-22.5 | 9.00-22.5 or 9.75-22.5 |

| Suspension | Mechanical suspension | Mechanical suspension |

| King Pin | 2.0 or 3.5 inch | 2.0 or 3.5 inch |

| Landing Gear | D200T or Chinese brand 28 tons (double-speed) | D200T or Chinese brand 28 tons (double-speed) |

| Main Beam | Height: 500 mm; Upper plate: 14 mm; Middle plate: 8 mm; Bottom plate: 16 mm; Material: Q345B steel | Height: 500 mm; Upper plate: 14 mm; Middle plate: 8 mm; Bottom plate: 16 mm; Material: Q345B steel |

| Brake System | WABCO RE 6 relay valve; T30/30 + T30 spring brake chamber (TKL brand) | WABCO RE 6 relay valve; T30/30 + T30 spring brake chamber (TKL brand) |

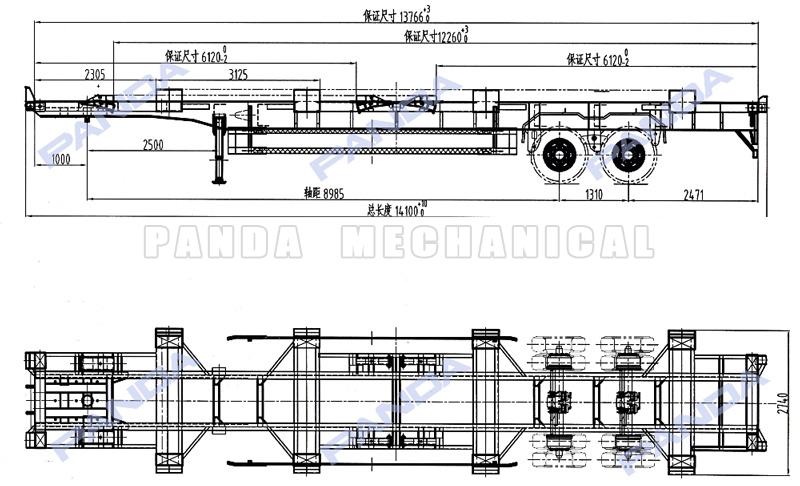

Bomb cart trailer drawing

40 footer bomb cart chassis drawing

Bomb cart trailer payloads

- 2 – 20′ Container (Twin-20)

- 1 – 40′ Container

- 1 – 45′ container

Bomb cart trailer images

40ft bomb cart trailer for sale

45 ft bomb cart trailer manufacturer

40ft bomb cart trailer for sale in China

Application of Bomb Cart Trailer

Bomb cart trailers move loaded ISO containers inside ports and container yards, working with terminal tractors to create high-throughput, low-cost internal transport between quay cranes, stacking yards, rail ramps, and gate areas.

Port & Container Terminals

20ft / 40ft / 45ft dry, reefer, and special containers

Quay crane ⇄ yard blocks ⇄ transfer lanes (high-frequency shuttle runs, single or twin-20ft handling)

40Ft bomb cart trailer Vs 40ft container chassis

| Dimension | Bomb Cart Trailer (Yard Use) | Container Chassis (Road Use) |

|---|---|---|

| Primary Use Case | In-terminal shuttling inside ports/rail depots/ICDs; works with quay/yard cranes; not intended for public roads. | Over-the-road transport from port to warehouse/customer; designed for public highways. |

| Transport Weight (Typical) | Yard, low-speed with higher overload margin: commonly ≤ 50–65 tons (depends on maker and yard SOP). | Constrained by road laws/axle loads: a 40 ft chassis ~25–36 tons payload (varies by country, axle set, tractor tare, compliance). |

| Move Frequency / Turnaround | High-frequency, high-throughput: side guides + twin-20 spacers enable faster box landing/alignment for repetitive short shuttles. | Moderate throughput: requires precise corner casting alignment and twist-lock engagement; suited to medium/long hauls. |

| Maintenance | Heavy-duty frame with simplified electrics/lighting; easy upkeep, less downtime, common spares; low cost per move. | Must meet road regulations (lighting, reflectors, guards, brakes, etc.); more maintenance items and compliance parts; cost depends on mileage/roads. |

How does the bomb cart trailer work?

A bomb cart trailer works together with a terminal tractor and quay/yard cranes to move loaded containers quickly and safely inside the port. The basic workflow is simple but highly organized:

Positioning at the quay or yard crane

First, the bomb cart trailer is positioned under the quay crane or yard crane in the designated lane. Operators confirm the correct lane, safety cones, and radio communication with the crane operator or signalman before any lifting starts.Connecting the terminal tractor

The terminal tractor then backs up to the bomb cart. The driver aligns the kingpin and fifth wheel, locks the coupling, and connects the air and electric lines. Panda Mech’s low-deck design helps keep the center of gravity stable during all movements.Receiving and securing the container

Once everything is in place, the crane lowers the loaded container onto the bomb cart. Twist locks, container guides, or pins are used to position and secure 20ft, twin-20ft, 40ft, or 45ft containers correctly on the deck.Safety and load checks

The operator performs a quick visual check of all locking points, corner fittings, and overall trailer stance. They make sure there is no dangerous overhang and that the load is properly distributed within axle limits.Internal transport in the terminal

After the checks, the tractor pulls the bomb cart along the designated terminal routes between the quay, yard blocks, rail ramp, or gate area. The driver maintains safe speed, follows one-way traffic rules, and keeps enough braking distance for heavy loads.Working with yard equipment

At the yard block, the bomb cart is positioned inside the stacking lane. The driver aligns the container centerline with the RTG/RMG, reach stacker, or other lifting equipment so the pick-up or drop-off can be done quickly and accurately.Operation in harsh conditions

During night shifts or heavy rain, the bomb cart relies on Panda Mech’s lighting, reflectors, and side guards to improve visibility and protect dockworkers moving around the trailer.Handling slopes and uneven ground

When the route includes slopes or rough surfaces, the driver controls speed and avoids sudden steering. The reinforced chassis and suspension on Panda Mech bomb carts help reduce sway and keep the container stable.Post-drop inspection

After the container is dropped off, the operator checks the deck, guides, and locking devices for any damage or foreign objects. Any abnormal noise, visible cracks, or misalignment is reported early to prevent unplanned downtime.Daily inspection and maintenance

Finally, routine checks are carried out on tires, brakes, air lines, pins, and welds. Thanks to Panda Mech’s simplified structure and accessible inspection points, daily maintenance is quicker, helping the bomb cart stay available and reliable in three-shift terminal operations.

How to Choose the Bomb Cart Trailer Manufacturer

Choosing the right bomb cart trailer manufacturer directly affects the safety, efficiency, and cost of every container move inside your terminal.

Safety & compliance:

Make sure the design meets port safety standards, local axle/GVWR rules, braking regulations, and terminal operating procedures. Ask for drawings, load calculations, and test reports. Whether you call it a bomb cart trailer or a terminal container trailer, Panda Mech provides clear structural analysis and braking performance data so your HSE team feels confident.

Engineering & structure:

Look closely at beam size, steel grade, deck thickness, container guide design, and welding quality. Check how the frame resists twisting on uneven yards and tight corners. As a proven port bomb cart supplier, Panda Mech uses high-strength steel, full-length longitudinal beams, and strict weld inspections to deliver long service life under three-shift operations.

Capacity & performance:

Confirm rated load, axle configuration, turning radius, and compatibility with 20ft, 40ft, 45ft, and twin-20ft operation. Ask for real data on cycle times, uptime, and typical TEU per shift. Panda Mech designs each yard container trailer to balance capacity, stability, and maneuverability for your specific terminal flows.

Integration & customization:

Your bomb cart trailer must match existing terminal tractors, RTGs/RMGs, and yard layout—not the other way around. Discuss options for kingpin height, twist-lock layout, container guides, bumpers, and lighting/guard packages. Panda Mech customizes each unit to your lane width, stack layout, turning pockets, and safety rules.

After-sales & lifecycle cost:

Don’t just compare prices on paper. Evaluate spare parts availability, warranty terms, training, and support speed. A well-built bomb cart trailer or terminal chassis trailer reduces downtime, repair costs, and accidents over its whole life. Panda Mech keeps core parts in stock, offers fast remote support, and focuses on low total cost of ownership for years of port service.

FAQ

What is a bomb cart trailer?

How much does a bomb cart trailer cost?

How much weight can a bomb cart trailer handle?

Where can I buy a bomb cart trailer?

Why use a bomb cart trailer transport container?

Are intermodal bomb carts the same as bomb cart trailers?

Talk WIth Us

- [email protected]

- 0086-15624389772

- Sunway Building, No.1110, Hualong Road, Jinan Shandong CHINA

- We will respond to you within five minutes.