Coal forms from ancient plant material buried and transformed by heat and pressure over millions of years, and I get it by mining it from the ground, either at the surface or deep underground. When I look at how is coal made, I see a process that starts with plant remains turning into peat, then changing slowly into different types of coal. Today, people mine coal in over 70 countries, with about 6,900 mines producing 8.9 billion tonnes each year.

How is coal formed

Coal forms when layers of dead plants get buried, pressed, and heated deep underground, slowly changing from peat into harder and more carbon-rich types of coal over millions of years. When I look at how is coal formed, I see a step-by-step transformation that starts with soft, spongy peat and ends with shiny, hard anthracite.

Stages of Coal Formation

Let me break down the main stages of coal formation for you. Each stage shows how plant material changes as it gets buried deeper and exposed to more heat and pressure:

- Peat 🌱

I see peat as the first step. It forms from dead plants in swampy, low-oxygen places. Peat is soft, wet, and has the lowest carbon content. - Lignite (Brown Coal) 🟫

When peat gets buried and squeezed, it turns into lignite. Lignite is still soft and brown, but it has more carbon and less water than peat. - Bituminous Coal ⚫

With more heat and pressure, lignite becomes bituminous coal. This type is harder, darker, and burns hotter. I often find it used for electricity and steel. - Anthracite 💎

The final stage is anthracite. It forms under the most heat and pressure. Anthracite is shiny, hard, and has the highest carbon content. It burns clean and hot.

Here’s a table that shows how the carbon and oxygen content changes as coal matures:

| Coal Rank Stage | Approximate Carbon Content (%) | Oxygen Content in Functional Groups (Wt.%) |

|---|---|---|

| Peat/Lignite | ~65.5 – 70.5 | High (OCOOH 8.0%) |

| Sub-bituminous | ~75.5 – 81.5 | Lower (OCOOH 0.3-0.6%) |

| Bituminous | ~85.5 – 88.6 | Very low (OCOOH near 0%) |

| Anthracite | ~90.3 | Minimal (OCOOH 0%) |

As coal moves through these stages, I notice the carbon goes up and the oxygen goes down. This makes the coal harder and better for burning.

Scientists use tests like vitrinite reflectance and look at things like hydrogen index and molecular biomarkers to track these changes. For example, in the Guaduas formation, I see that coal with higher maturity has more carbon, less ash, and less sulfur.

Types by Formation

When I talk about how is coal formed, I also look at the different types of coal that come from this process. Each type forms under different conditions and has its own uses.

- Peat: Soft, brown, and full of plant pieces. Used in gardens and sometimes as fuel.

- Lignite: Brown coal, more compact, higher energy than peat. Used in power plants.

- Bituminous Coal: Harder, black, and shiny. Used for electricity and making steel.

- Anthracite: Hardest and shiniest. Burns the hottest and cleanest. Used for heating.

I find that the type of coal depends on how deep it was buried and how much heat and pressure it felt. The deeper and hotter, the harder the coal.

The timeline of coal formation started in the Carboniferous Period, when giant plants covered the Earth. These plants died, fell into swamps, and started the journey from peat to anthracite. Over millions of years, geological changes, microbial activity, and chemical reactions turned plant debris into the coal we use today.

Types of Coal

Peat

Peat is the very first step in the coal family. When I walk through a swampy area, I sometimes see peat forming right under my feet. It looks like dark, spongy soil and feels wet to the touch. Peat comes from layers of dead plants that pile up in places where water keeps out the air. Because of this, the plants don’t rot away completely.

- Peat is soft and crumbly.

- It holds a lot of water.

- People sometimes use it in gardens or as a low-energy fuel.

I think of peat as the “baby” of the coal world. It has the lowest carbon content and doesn’t burn as hot as other types. Most power plants don’t use peat because it doesn’t give off much energy.

Lignite

Lignite is the next step after peat and is often called brown coal. I notice lignite when I see a soft, brownish-black rock that breaks apart easily. It forms when peat gets buried deeper and starts to dry out. Lignite has more carbon than peat, so it burns better, but it still isn’t as powerful as other types of coal.

Here’s what stands out about lignite:

- It has a higher energy content than peat, but less than bituminous coal.

- Lignite is mostly used in power plants close to where it’s mined.

- It makes up about 8% of the U.S. coal market.

Did you know? Countries like Germany, India, and China produce a lot of lignite. I see lignite mines in many parts of Europe and Asia, where it’s an important source of electricity.

Bituminous

Bituminous coal is the most widely used type of coal in the world. When I hold a piece of bituminous coal, I see a hard, black rock that feels heavier and denser than lignite. This coal has a much higher carbon content, which means it burns hotter and longer.

Let me show you how these types compare:

| Coal Type | Carbon Content (%) | Energy Content | U.S. Market Share (%) | Global Market Share (%) |

|---|---|---|---|---|

| Peat | ~60 | Very low | N/A | N/A |

| Lignite | 25 – 35 | Lowest | 8 | N/A |

| Bituminous | 45 – 86 | High | 46 | 35.67 |

Bituminous coal stands out for a few reasons:

- It powers most of the world’s electricity plants.

- I see it used in making steel, cement, and even chemicals.

- It holds about 35.67% of the global coal market, making it the top choice for many industries.

Bituminous coal is harder to ignite than lignite, but once it starts burning, it gives off a lot more heat. That’s why I think of it as the “workhorse” of the coal family.

When I compare bituminous coal to lignite, I notice that bituminous has more carbon, less moisture, and a stronger coking tendency. This makes it ideal for industrial applications, particularly when high heat or coke is required.

Anthracite

Anthracite is the hardest, shiniest, and most energy-packed type of coal. When I hold a piece of anthracite, I notice how dense and glossy it feels. It almost looks like a black gemstone. I always tell people that anthracite stands out from other coals because of its high carbon content and powerful heat.

Here’s what makes anthracite special:

- Very high carbon content: Usually between 92% and 98%. That’s higher than any other coal type.

- Highest energy value: Anthracite gives off more heat per pound than other coals, making it a top choice when I need strong, steady heat.

- Low volatile matter: It doesn’t have much material that burns off quickly, so it needs special boilers to burn well.

- Hard and shiny: It’s tough to break and has a glassy shine.

- Scarce and valuable: Anthracite is rare. In the United States, I find almost all of it in northeastern Pennsylvania. It makes up less than 1% of all coal mined in the country.

Because anthracite is so hard to find and needs special equipment to burn, I usually see it used in metal industries or for home heating where clean, hot fuel is needed.

Technical studies show that anthracite’s fixed-carbon content ranges from about 86% to 98%. Its low moisture (3–6%) and low volatile matter (2–12%) mean it burns slowly and cleanly. I’ve read that its scarcity comes from limited deposits and the need for special combustion methods. That’s why anthracite is prized but not used as widely as other coal types.

Key Differences

The primary differences between coal types stem from their carbon content, energy value, and ease of combustion. I like to compare them side by side so you can see what sets each one apart.

| Coal Type | Carbon Content (%) | Energy Value (BTU/lb) | Volatile Matter (%) | Typical Use | Color & Texture |

|---|---|---|---|---|---|

| Peat | ~60 | Very low | High | Gardens, low fuel | Brown, spongy |

| Lignite | 25–35 | Low | High | Power plants | Brown, crumbly |

| Bituminous | 45–86 | Medium to high | Medium | Electricity, steel | Black, soft to hard |

| Anthracite | 86–98 | Highest | Very low | Metal industry, heat | Black, shiny, hard |

- Peat is soft and wet, not great as a fuel.

- Lignite is better, but still not very powerful.

- Bituminous is the workhorse, used in most power plants and industries.

- Anthracite is the king of heat, but rare and needs special care to use.

I always remember: the higher the carbon, the more energy the coal gives off. Anthracite wins in both, but I don’t see it everywhere because it’s so scarce.

When I look at how different coals react in gasification studies, I notice that coals with more volatile matter (like lignite) produce more gas and react faster. Anthracite, with its low volatile matter, burns slower and needs higher temperatures. That’s why each type of coal fits a different job, from garden fuel to powering big factories.

How is coal mined

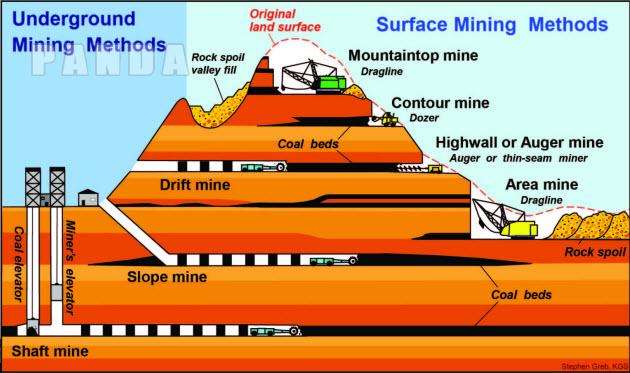

To understand how coal is developed, we need to know how it is generally buried.

Coal is generally buried in two ways, respectively open pit mining, and underground mining. Surface mining is defined as within 200 feet of the surface, and underground mining is generally defined as more than 200 feet above the surface.

They are mined in different ways. Open-pit mining is easier, while underground mining is more complicated and dangerous for coal miners.

Open pit mining:

Strip mining is the easiest form of mining, with the coal seam very close to the surface. Mining usually involves removing overburden, removing soil and rock with excavators, etc., then drilling, fracturing and systematically stripping with excavators, and finally transporting with the dump truck, semi tipper trailer or semi tipper trailer.

Strip mining can be used in both flat and hilly landscapes. Strip mining in a mountainous area is called contour mining. Contour mining follows the ridges, or contours, around a hill.

Open pit mining usually involves:

- Remove part or all of the buried coal seam to expose it.

- Dispose of excess material in nearby valleys.

General mining is divided into the following five steps:

- First, remove the rock layer and soil layer above and between the coal seam.

- After the coal seam is removed, there will be a lot of excess soil and rock, which will be put into the adjacent valley.

- Use large earthmoving equipment to start digging coal. Select different equipment according to the mining method and scale.

- As coal mining continues, it may need to be re-graded according to specific circumstances.

- After coal mining is completed, methods such as covering vegetation are usually used to reduce pollution.

What does strip mining do to the land?

Coal mining creates big holes in the ground, so when the coal is removed, we need to restore the mine. We need to make a plan and repair it gradually.

Underground mining

When coal seams are deep underground, I use underground mining. This method lets me reach coal that sits far below the surface. Here’s what I do:

- 🕳️ I dig shafts or tunnels down to the coal seam.

- 🚇 I build passageways so my team and machines can reach the coal.

- ⛏️ I cut the coal from the seam using machines or hand tools.

- 🚂 I move the coal to the surface using conveyor belts or carts.

- 🛑 I support the tunnels with steel or wood to keep them safe.

Underground mining takes more planning and safety checks. I watch for risks like cave-ins or gas leaks. My team wears safety gear and follows strict rules. I also use special machines to measure air quality and tunnel strength.

Room and pillar mining

When is this method used?

Room and pillar are usually used for flat-lying deposits.

How does it work?

In room-and-pillar mining, coal deposits are mined by cutting a network of ‘rooms’ into the coal seam and leaving behind’ pillars’ of coal too. Coal deposits are mined by cutting a network of ‘rooms’ into the coal seam and leaving behind’ pillars’ of coal to support the roof of the mine. These pillars can be up to 40% of the total coal in the seam – although this coal can sometimes be recovered at a later stage.

Longwall mining

When is this method used?

Longwall mining is used to mine a long wall of coal in a single slice.

How does it work?

Longwall mining involves the full extraction of coal from a section of the seam, or ‘face’ using mechanical shearers. The coal ‘face’ can vary in length from 100-350m. Self-advancing, or ‘face’ using mechanical shearers. The coal ‘face’ can vary in length from 100-350m.

Self-advancing, hydraulically-powered supports temporarily hold up the roof while coal is extracted. When the coal has been extracted from the area, the roof is allowed to collapse. Over 75% of the coal in the deposit can be extracted from panels of coal that can extend 3km through the coal seam.

Transport

Finally, move coal from the mine to where people need it. This is how coal is transported to power plants, factories, or ports for shipping. I use trains, tipper semi trailers, barges, and even conveyor belts.

Conclusion

Common coal mining methods for these two, usually we mining, will be based on their actual situation to choose. No matter what kind of mining method is used, we should not ignore the impact on the ecology after the completion of mining. We need to repair the environment by some means.

Refer: https://en.wikipedia.org/wiki/Coal

FAQ

What are the steps of coal formation?

Coal is formed in four stages: peat, brown coal, bituminous coal, and anthracite. If there is more pressure and heat in the place where the coal is buried, better anthracite will be produced.

Is coal a renewable energy source

No, coal is a non-renewable energy source. Similarly, fossil fuels, like coal, are non-renewable energy sources, as well as oil and natural gas. They all take hundreds of millions of years to produce.

Maybe you want

-

Coal Dump Trailer For Sale

$11,900.00